Noctua spent four and a half years designing its quietest, strongest fan yet

200 prototypes later, the mad airflow scientists at Noctua have made a new type of plastic for their best fan yet.

Austrian fan company Noctua might've been the only company at Computex without a single RGB LED in sight. In fact, one of the new fan lines at Noctua's booth is a black version of its renowned quiet consumer fans, which have, up to this point, only come in the company's typical brown and tan color scheme. Those colors, it turns out, aren't exactly popular with PC gamers who want all the components in their case to match. Aesthetically, Noctua's a bit behind the curve. Perhaps that's because when it comes to fan performance, they're so far ahead of it.

Noctua's next-generation A-series fan has been in development for more than four years, with more than 200 prototypes leading to the material and shape it's finally taken. That's a lot of time to design anything, let alone a fan. Which, if you'd asked me about before visiting Noctua's booth, I would've assumed we had pretty well figured out by this point. But apparently there's still a lot of potential there.

For starters, Noctua has ditched PBT, a plastic commonly used in fan blades and keyboards and all kinds of other things. "We're using a completely new plastic compound," says Noctua's Jakob Dellinger. "We call it Sterrox."

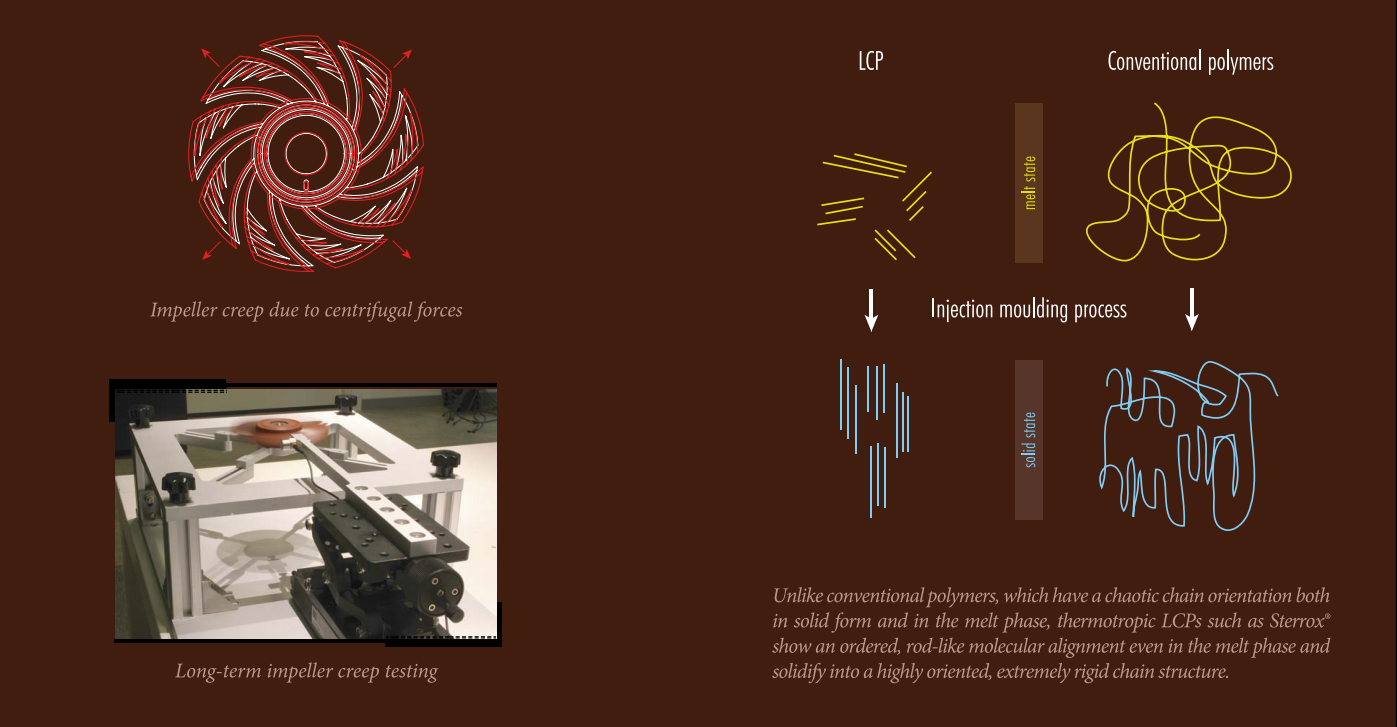

Sterrox, Dellinger explains, is a liquid crystal polymer, part of the same family as Kevlar. "The basic feature of these types of plastics is that the molecular chain structure is fairly ordered already in the liquid state when you push it into the injection mold, and it gets to a very organized aligned structure once it hardens out in the mold," he says. "Whereas conventional polymers are completely chaotic in the liquid state and still fairly chaotic in the solid state. Why does it matter? Because the aligned molecular structure gives it way more rigidity. You can feel it. It's way less flimsy than your average fan."

It's an emergency-only material from an engineering point of view because the raw material cost is roughly four times as high as PBT.

Jakob Dellinger, Noctua

Touch the new blade and the difference is immediately apparent. This is an unusually dense, firm, and inflexible plastic. I don't think I've ever seen a fan blade like it before, and certainly not a PC fan.

Noctua didn't set out to use a liquid crystal polymer in its new fan. Dellinger calls it an "emergency-only material" for engineers, because it costs about four times as much as PBT. So no, this new fan's not going to be cheap. But it also seems poised to blow away the competition, including Noctua's existing fans.

What's the value of a more rigid fan blade? There are two big ones for this design. The first is that it allows the fan to be quieter. A lot of work goes into creating a near-silent fan. The entire unit vibrates, causing noise, which is why Noctua and some other companies package their fans with anti-vibration pads on the corners. But there are also smaller, micro-vibrations on the surface of the fan blade itself.

The biggest gaming news, reviews and hardware deals

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

As a fan blows, pressure on one side is greater than the pressure on the other. "From an aero-acoustic point of view, this is quite similar to what you have in a stereo speaker," Dellinger says. "You have the membrane, and higher pressure inside and lower pressure outside, and this pressure distance creates a very efficient acoustic coupling between the surface of the membrane, in the case of the speaker, and the fan blade, in the case of the fan, and the air. So you can transmit vibrations from the surface to the air very efficiently. Which is nice for the speaker, but not so nice for the fan."

The new material produces fewer vibrations, which means less noise. But there's another, way more interesting reason for using Sterrox.

Noctua's new A-series fan has a tiny tip clearance—the space between the fan blades and the housing—of about 0.5 mm. This will make the fan more efficient, particularly when used in air coolers and radiators. "When you have a fan blowing against a heatsink or a radiator, it builds up pressure," Dellinger says. "You have leak flows going back through that gap, and the bigger the gap, the bigger the leak flows. The narrower the gap, the less leak flows you have. So when you have a very narrow gap, it allows you to push more air through heatsinks and radiators."

But why can't you do that with PBT? I asked if it was because of wobble in the less rigid plastic, but it's actually because fan blades tend to get longer over time, as they spin for months and years. This is called impeller creep.

"When you have the impeller running for years, the centrifugal forces will draw the material outwards," says Dellinger. "So you'll see the impeller getting just so slightly bigger. We're talking just about 0.1, 0.2 millimeters. Nobody cares about that if you have a usual gap size of 2mm or 1.5mm, but if you're aiming for 0.5, it's really a problem. So we need a material that has better tensile strength, and thus allows us to manufacture such a tight gap."

So this new fan is better at pushing air, and it's quieter while it does it. But how much better? Noctua had a demo set up comparing the new fan against two of its NF-F12 fans, each attached to an identical heatsink on an identical processor. The end result? Dead even, one fan versus two.

Dedicated PC builders might be wondering, at this point: sounds awesome, but is it a static pressure fan or an airflow fan? Neither, says Dellinger, but he also says it's not a compromise. In practical situations, this new fan is better at high pressure and at high airflow than Noctua's more specialized fans, as you can see on this chart.

So why does it look like Noctua's existing, more specialized fans are better at either pressure or airflow? Technically, they do, but Dellinger says those values are mostly worthless.

"Max airflow ratings and max pressure ratings don't mean much at all. Maximum airflow is measured at zero pressure, so that means the fan is not even operating in free air; there is zero pressure difference between the two sides. So it's basically operating in vacuum. Not a realistic application. Maximum pressure is at zero airflow. that's the fan blowing against a closed wall. Not a realistic application either.

"What you really want to know is how much air the fan can push against realistic resistance, and this is what you see in the mid part of the curve. And when looking at the resistance curves and impedance curves of a typical PC case, fairly low resistance, but still way more than vacuum. Where it really shines is on air cooling heatsinks where it can push way more air than the NF-F12, and on watercooling radiators where it can push way more air than the current generation.

With all the A-series fans, the idea is to basically get rid of that distinction between pressure and airflow optimization.

Jakob Dellinger

"We were surprised, to be honest, in the end, that we could make the performance that good at the airflow end of the spectrum as well. But with all the A-series fans, the idea is to basically get rid of that distinction between pressure and airflow optimization, because it is confusing for a lot of customers. A lot of customers don't know what to shop for. Some just think static pressure is better, for some reason, and buy it for case usage, and then are dissatisfied. So we think it's safer and easier for the customer if there's one fan that does it all."

Hopefully you found that bit of fan science as fascinating as I did. This isn't the first fan to claim it's great at both airflow and static pressure, but if it lives up to Noctua's reputation, it'll likely be the quietest fan to do so.

Dellinger says the 120 mm model will even outperform most 140 mm fans on the market when it's released this fall, and Noctua plans to release an adapter mount for 140 mm fittings. Which is good news, since a 140 mm model likely won't be available for at least a year. Apparently that's not as simple a matter as making everything 20 mm bigger; Noctua has to redesign the fan blade for a larger body.

There's no official price, yet, but a Noctua NF-F12 fan costs $20, and the raw materials for the Sterrox blade are, as Dellinger says, about four times more expensive. I don't think this will be an $80 fan, but expect it to command a premium price.

Wes has been covering games and hardware for more than 10 years, first at tech sites like The Wirecutter and Tested before joining the PC Gamer team in 2014. Wes plays a little bit of everything, but he'll always jump at the chance to cover emulation and Japanese games.

When he's not obsessively optimizing and re-optimizing a tangle of conveyor belts in Satisfactory (it's really becoming a problem), he's probably playing a 20-year-old Final Fantasy or some opaque ASCII roguelike. With a focus on writing and editing features, he seeks out personal stories and in-depth histories from the corners of PC gaming and its niche communities. 50% pizza by volume (deep dish, to be specific).