Inside Logitech: How gaming mice are built and tested

I spent a day touring Logitech's headquarters in Lausanne, Switzerland, which are located right next to the campus of EPFL, an internationally renowned engineering school. A couple floors above ground, there's a room packed with keyboards and mice being hammered on, tested for reliability for hours on end. Underground, however, is where the real magic happens—that's where Logitech's labs house sophisticated machines built to test the sensors its engineers design.

Before we saw the second example below, used to test the mice movements of up to 500 inches per second, Maxime Marini, Logitech's senior director of engineering, had this to say about Logitech's lab:

"Today, if you buy your mouse from a competitor, you will see some spec on the box. So, that spec, it will come from where? From the chipmaker. Now, the question is, where is the chipmaker getting that spec? This machine...They really come here to test it, because they can’t test it themselves. We are enabling the full industry. We are setting the standard."

Marini's proud, but after touring Logitech's headquarters, it's easy to see why. I haven't been inside the facilities at companies like Razer or Steelseries, or the sensor makers like Pixart, which Logitech works with. They may have some equipment similar to what Logitech has in its Swiss labs. But the machine used to test the G402 below is certainly one-of-a-kind, because no one aside from Logitech has built a gaming mouse that comes close to tracking at 500 inches per second.

Springloaded arm for testing tracking speed

The G402's "Fusion Engine" pairs a sensor accurate at low inch-per-second movement speeds with an accelerometer that's very accurate at high movement speeds.

Said senior engineer François Morier: "We had to make an arm that was spring operated, because at the beginning of the project we just wanted to have a very basic arm to validate, to be able to break the speed of the optical sensor and to see the transition between optic and accelerometer to make sure that this happens correctly. This is just moving the mouse. The speed here is about 250, 280 ips. It’s sufficient to break the speed of the optical sensor, but it is not sufficient to [break the accelerometer]. So we had to create another one. It has been used to validate that the mouse is the fastest in the world."

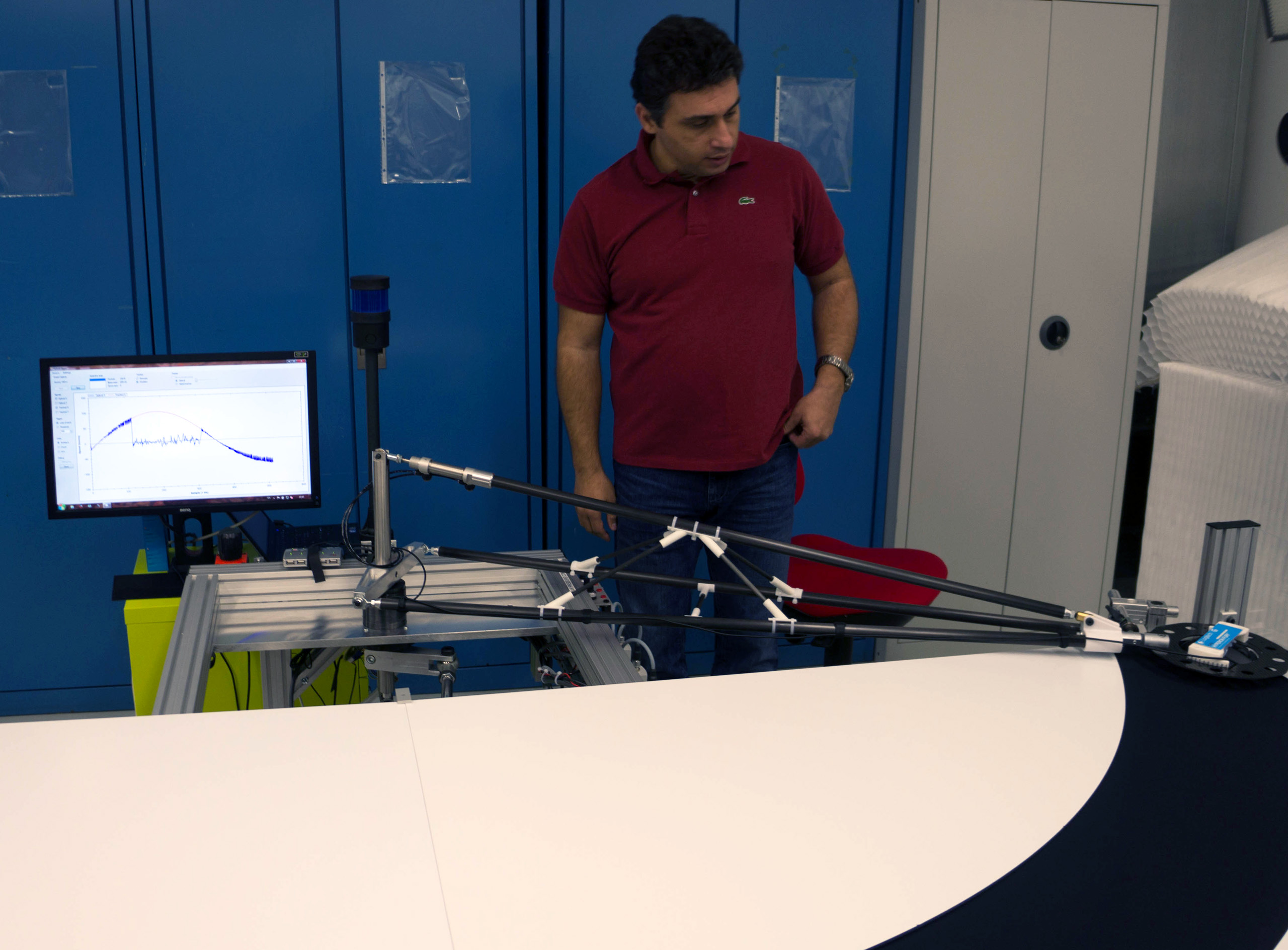

Air pressure arm for testing tracking speed

Check out the video on the first page (or jump to it on Youtube) to see this one in action.

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

Here's the second arm Logitech built to test the G402 (and other mice, but mostly the G402's sensor-to-accelerometer hand-off). The screen to the left charts data from the mouse in real-time, and shows the sensor losing accuracy (and then regaining it) as the mouse moves too quickly and then slows down again. In the middle, the accelerometer takes over, with no delay in the hand-off.

"They were kind of disappointed with me when I told them [the first arm] wasn’t going fast enough," senior product manager Chris Pate said with a laugh. Where the first arm topped out at around 280 inches per second, this one tested the G402 to about 500 inches per second. The mouse is actually capable of tracking at even faster speeds, according to Logitech; this arm still wasn't enough to overcome its tracking. While the arm can move at faster speeds when it's charged with more air pressure, more pressure causes vibration which throws off the results.

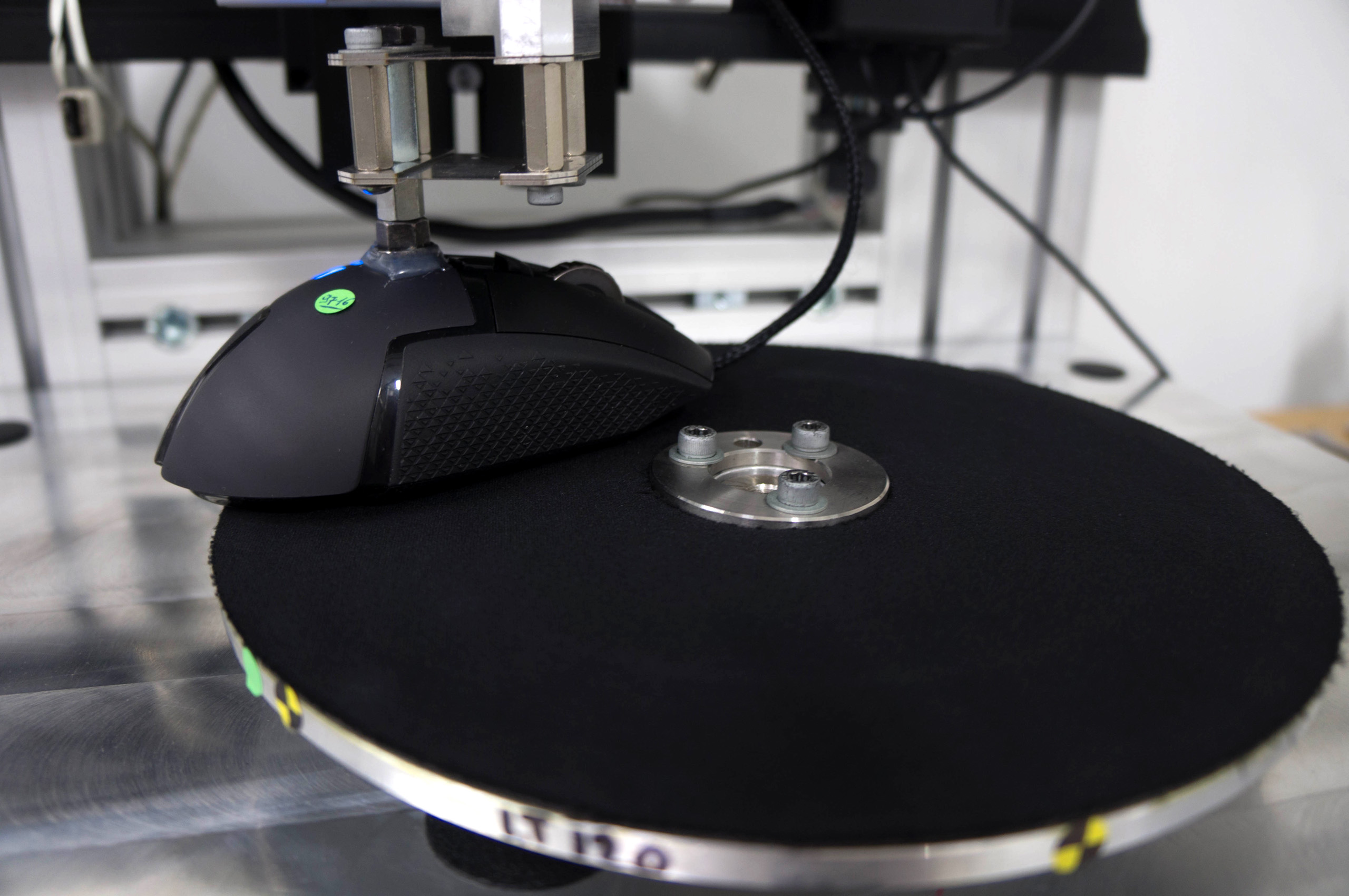

Turntable for surface testing speed, acceleration, and latency

François Morier: "This setup is a turntable that has been designed and used to validate maximum speed, maximum acceleration, as well as latency. With this machine we can change the disk so we can move different kinds of surfaces. The performance of the sensor is very dependent on the surface. Especially depending on the optical configuration, the angle of illumination, you’ll be able to work on shiny surfaces or not. This depends on your optical configuration. With our new designs we try to make the surface calibration, the ability to work on different surfaces, as large as possible."

The G502 includes a surface tuning feature to fine-tune the sensor for a specific mouse pad or desk. When the mouse is tuned to a particular surface, it won't track as well on another surface, but it will be able to track accurately at higher inches per second and support a lower lift-off distance on your surface of choice.

Mouse acceleration testing

Logitech had a similar turntable machine, which I forgot to grab a photo of, built to test mouse acceleration. The mouse would be quickly swiped in one direction, then slowly returned to its starting position. The machine was hooked up to a system running Counter-Strike; it would fire off a shot, then show that after the fast swipe and slow return, the cursor lined up on the exact same spot.

Acceleration is one of the big no-nos of gaming mice; when a sensor exhibits acceleration, that means that the cursor will move a different distance based on the speed you move the mouse. Swipe fast and the cursor moves further (or not as far) as a slow swipe. That inconsistency can make it hard to judge exactly where your pointer will be. Logitech proudly proclaims the new G502 exhibits absolutely no acceleration.

Chris Pate, referring to the test machine: "This specific mouse was collected from a user who was experiencing what he felt to be inaccuracy or acceleration. So I contacted him, got the mouse back, got him a different one, shipped it off to François to validate. Because it’s not that we’re trying to prove that anybody’s wrong. We want to make sure that everything we do meets the standards that we’ve set. So in the event that there was something wrong with the mouse, we collected it to make sure, and we validated that it actually does perform as we’ve specified. We narrowed it down to one of two things. Either the USB port that he was using, or the fact that he was removing the weight door to reduce the weight because he wanted a lighter mouse, and if you remove the weight door it removes one of the feet, and you can actually pick the sensor up a little bit when you’re swiping it."

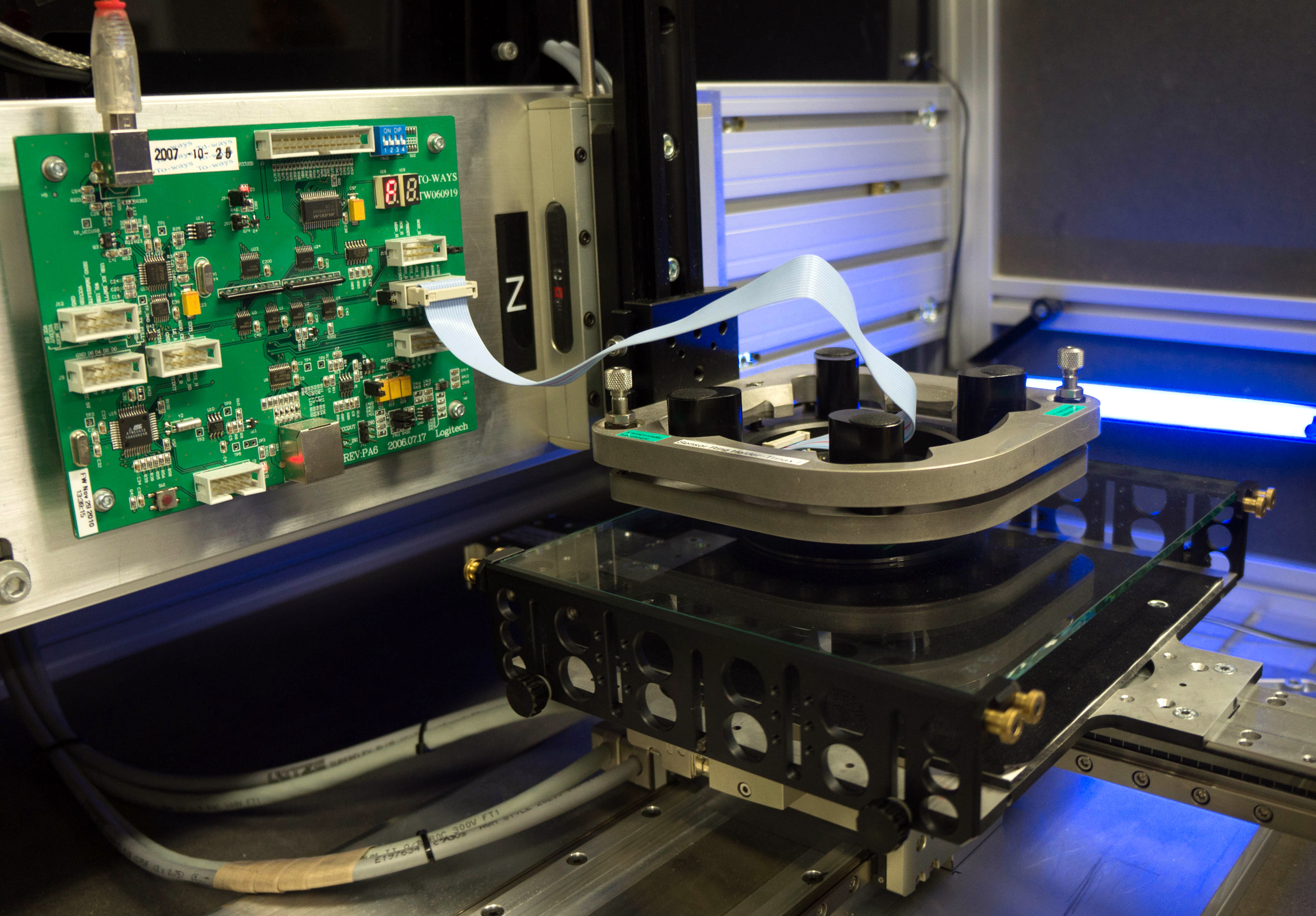

Glass tracking

One of Logitech's non-gaming mice tracking on a glass. Morier and his other engineers spent months developing a sensor to that could track on glass surfaces. It's built for office mice, not gaming mice; it doesn't track at the speeds or DPI levels gamers want, but is a great technology for office workers with glass desks.

Keyboard reliability testing

Logitech’s keyboard testing machine presses 13 keys per second to ensure that its new Romer-G switches can stand up to 70 million keypresses. After 70 million presses, says Logitech, the keys must be within a 30% threshold of their original keyfeel. Part of the G910 Orion Spark’s reliability comes from a dual contact design. Unlike the Cherry switches that the vast majority of mechanical keyboards use, the Romer-G switches have two metal contacts that register a keypress, not one. If one of those contacts breaks (or is taken out of commission by dirt or soda) the keyboard will continue to function normally.

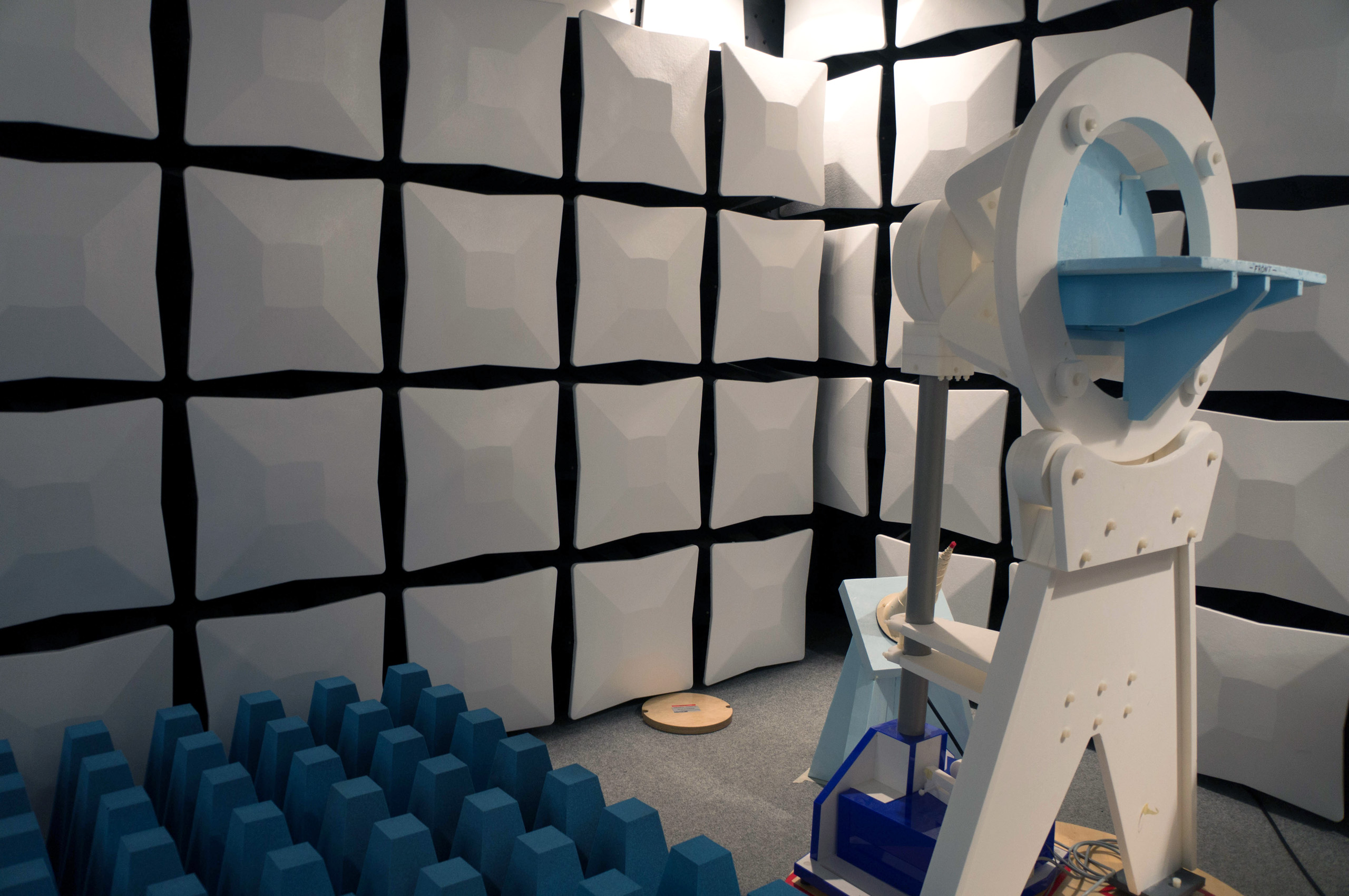

Anechoic chamber

Logitech built an anechoic chamber to develop its wireless mice. In order to accurately study the radiation patterns of its wireless mice—to ensure that the mouse will remain in contact with its receiver, regardless of its position relative to the computer—they had to cancel out interfering signals from Wi-Fi networks and other radio waves. Mice, laptops with attached receivers, etc. are placed on the light blue platform for analysis.

After touring through Logitech's facilities, I spent about two hours talking to Pate and Morier about all things gaming mice. Look for more coverage from my trip to Logitech, including a deep dive into mouse sensors, in the near future.

Wes has been covering games and hardware for more than 10 years, first at tech sites like The Wirecutter and Tested before joining the PC Gamer team in 2014. Wes plays a little bit of everything, but he'll always jump at the chance to cover emulation and Japanese games.

When he's not obsessively optimizing and re-optimizing a tangle of conveyor belts in Satisfactory (it's really becoming a problem), he's probably playing a 20-year-old Final Fantasy or some opaque ASCII roguelike. With a focus on writing and editing features, he seeks out personal stories and in-depth histories from the corners of PC gaming and its niche communities. 50% pizza by volume (deep dish, to be specific).