How motherboards are designed and manufactured: inside MSI

We traveled to MSI's factory in China and offices in Taiwan to see both R&D and production for motherboards.

MSI’s manufacturing facility outside Shenzen, China is massive. Seriously: the complex, which I visited in late May, currently houses approximately 7000 employees, according to the facility’s director. Many of those employees work to produce thousands of motherboards and graphics cards every single day, along with full tower PCs, all-in-ones, and vehicle entertainment products (though we know them as a computer hardware company, MSI makes many other products in China, too).

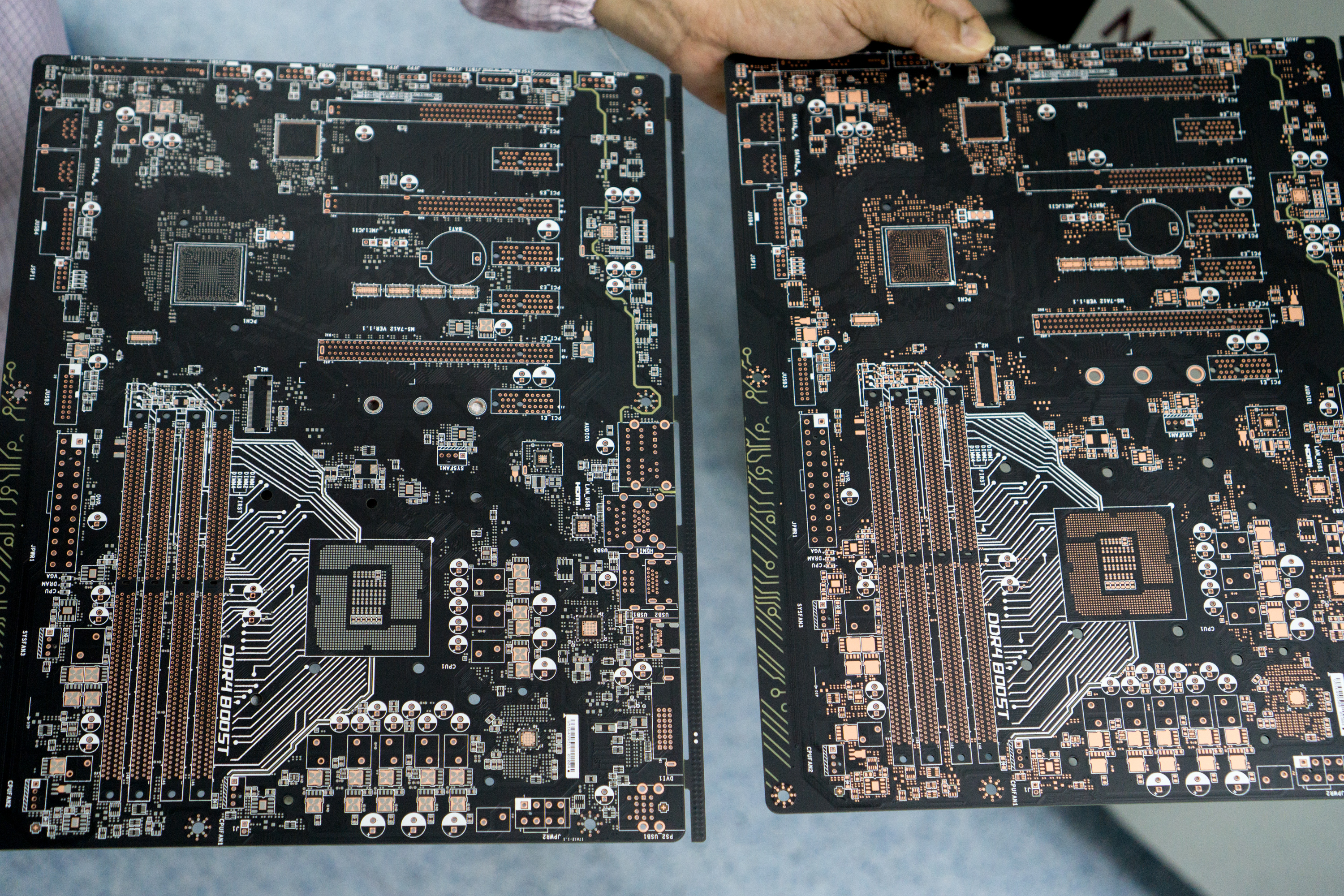

I traveled to MSI’s factory to see how it builds motherboards, and how its process has changed in recent years to make MSI a stronger competitor to Gigabyte and Asus. For a fun comparison, look at MSI’s facility in the following gallery side-by-side with our tour of Gigabyte from 2015. If you’re interested in more than motherboards, stick around for the last 11 slides in the gallery, which are from MaximumPC EIC Tuan Nguyen’s trip to another MSI facility, their office in Taiwan, where he got to see their R&D and design process.

These pick-and-place machines have thousands of tiny electronic components on those reels in front. The reels are fed into the chamber and slotted into place on the motherboard. All those tiny resistors and other chips scattered across the motherboard are attached in these machines in a very fast automated process.

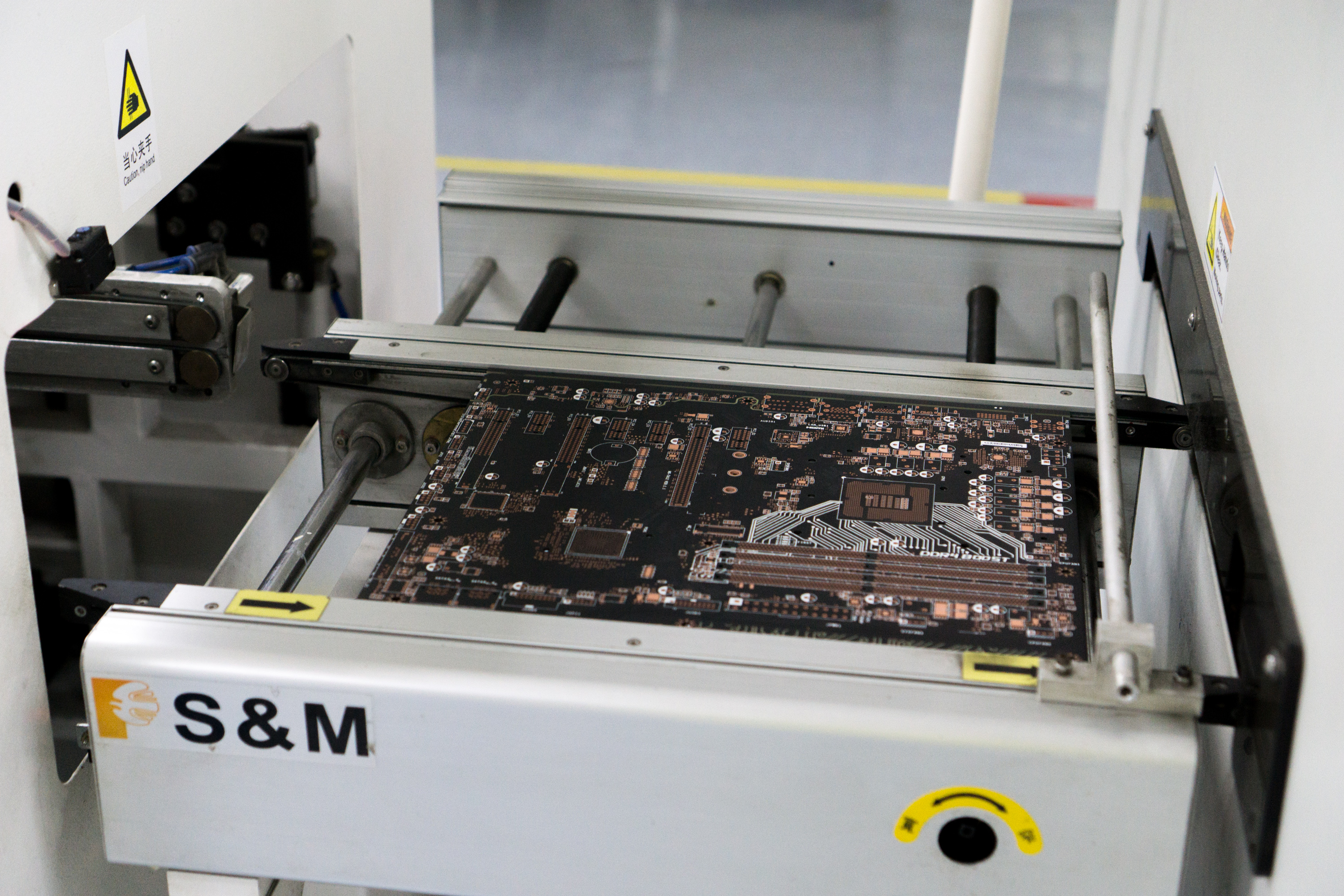

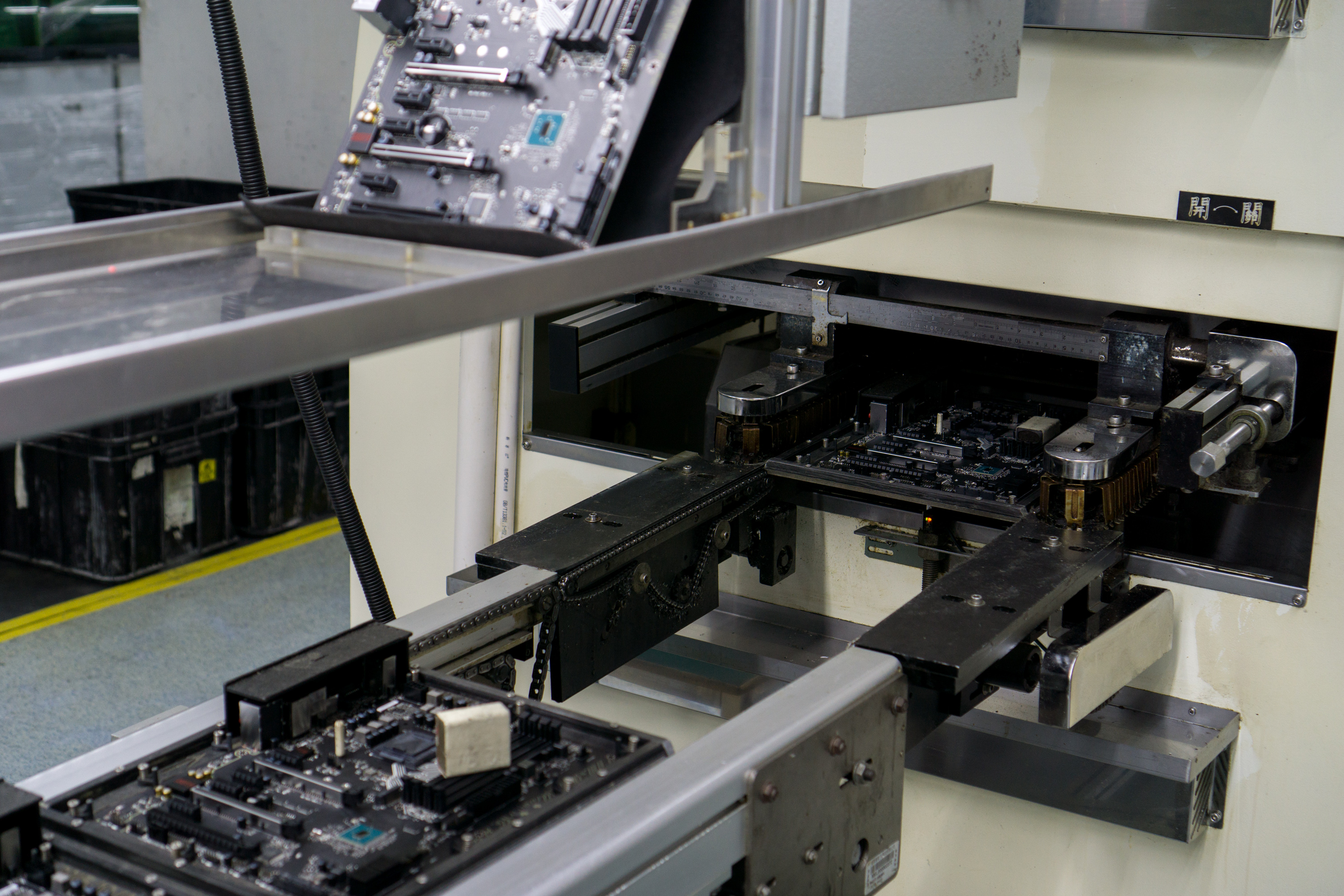

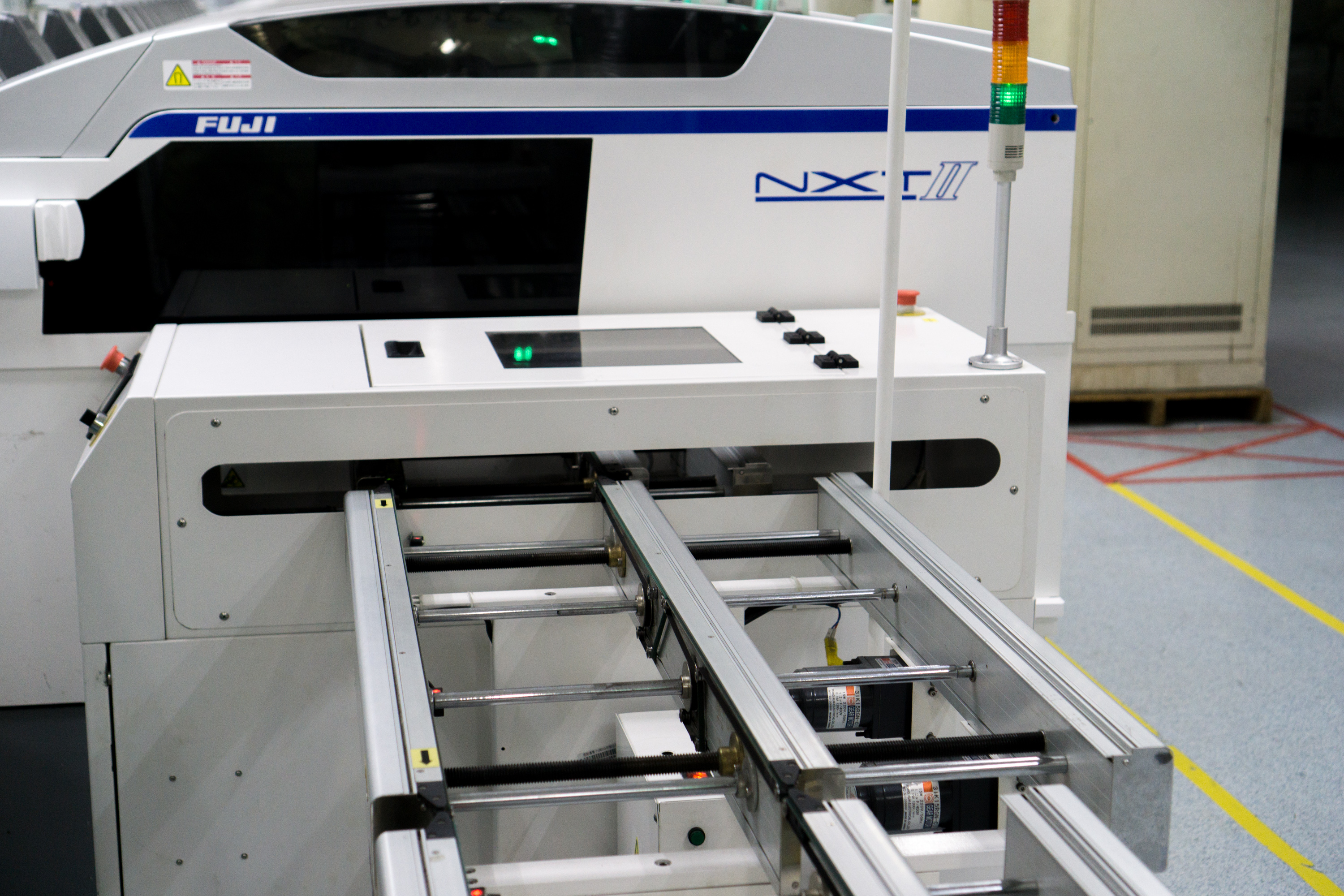

A close up of a pick-and-place machine, also referred to as a chip shooter. You can read more about the SMT (surface mount technology) process here. You can't see inside, but there's a conveyor belt rolling the through with the motherboards.

A look back at the side of the pick-and-place machine, where motherboards emerge once they've been imprinted with circuitry.

According to manufacturer Fuji's website, the NXT III (the successor to the machine pictured above) can place 37,500 chips per hour, 44 percent faster than the NXT II. There's also a great video at the link above that shows the robotic mounting arm inside placing those chips. As you can imagine, it's pretty fast.

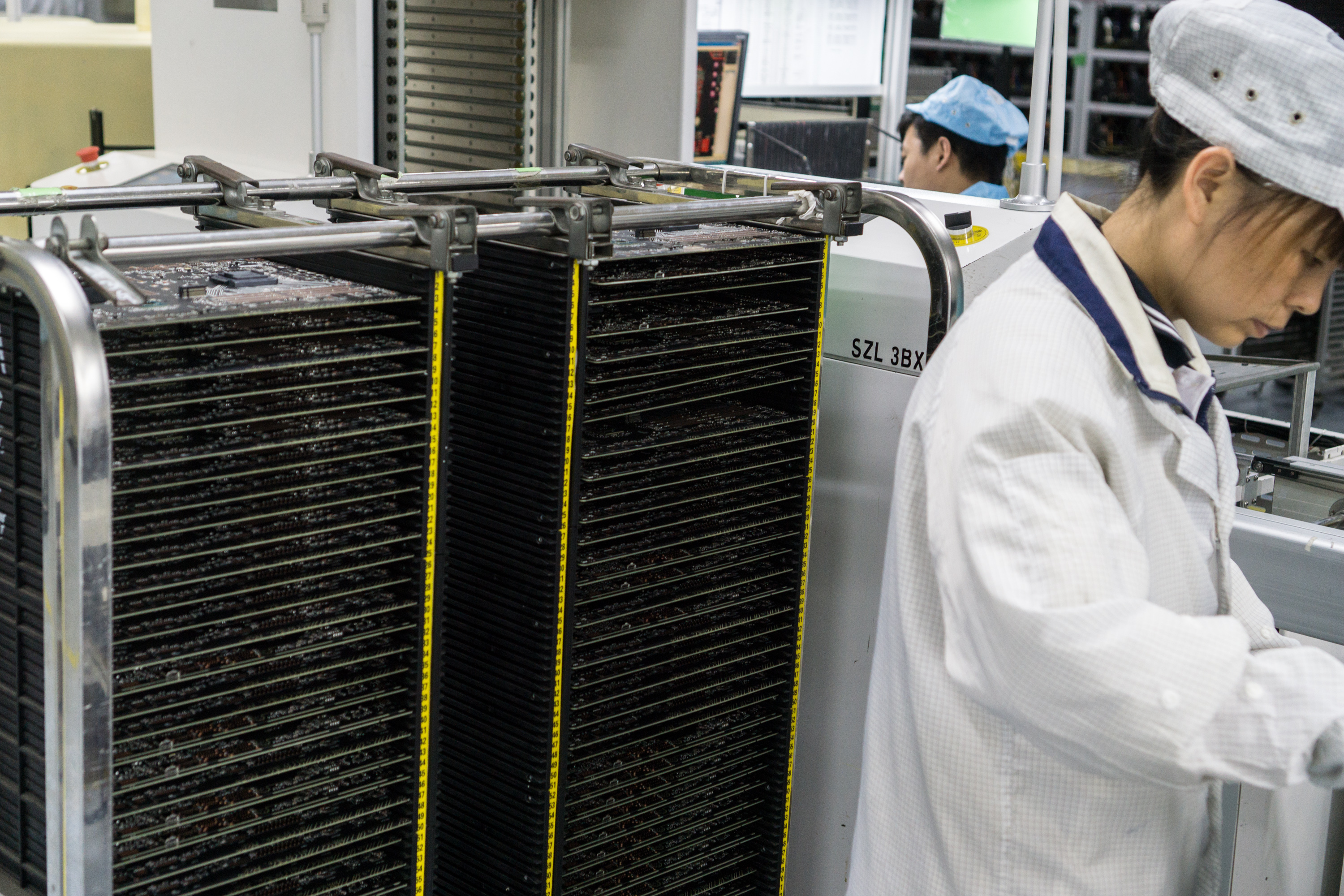

Motherboards on motherboards on motherboards. Here trays of in-progress boards await their turn to go onto the next stage of assembly, where more components will soon be added.

MSI's factory director explained that in recent years they've had to train employees to be be flexible and have wider skillsets in the past, because production styles are changing. High volume manufacturing used to be the norm, meaning they'd crank out thousands of a single product for days or even months. Now the manufacturing is far more mixed, meaning they change which boards are being produced frequently (sometimes as often as three times a day).

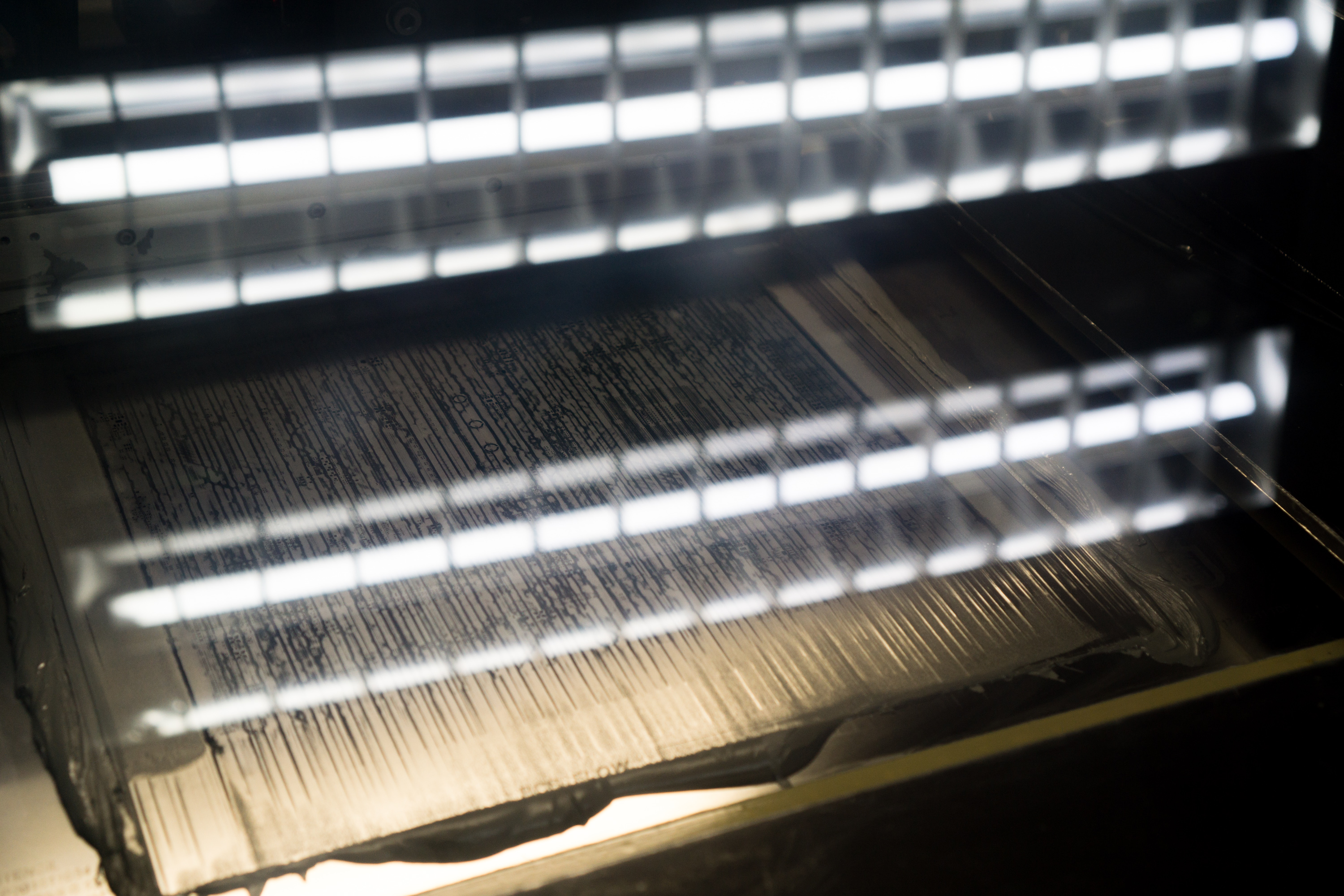

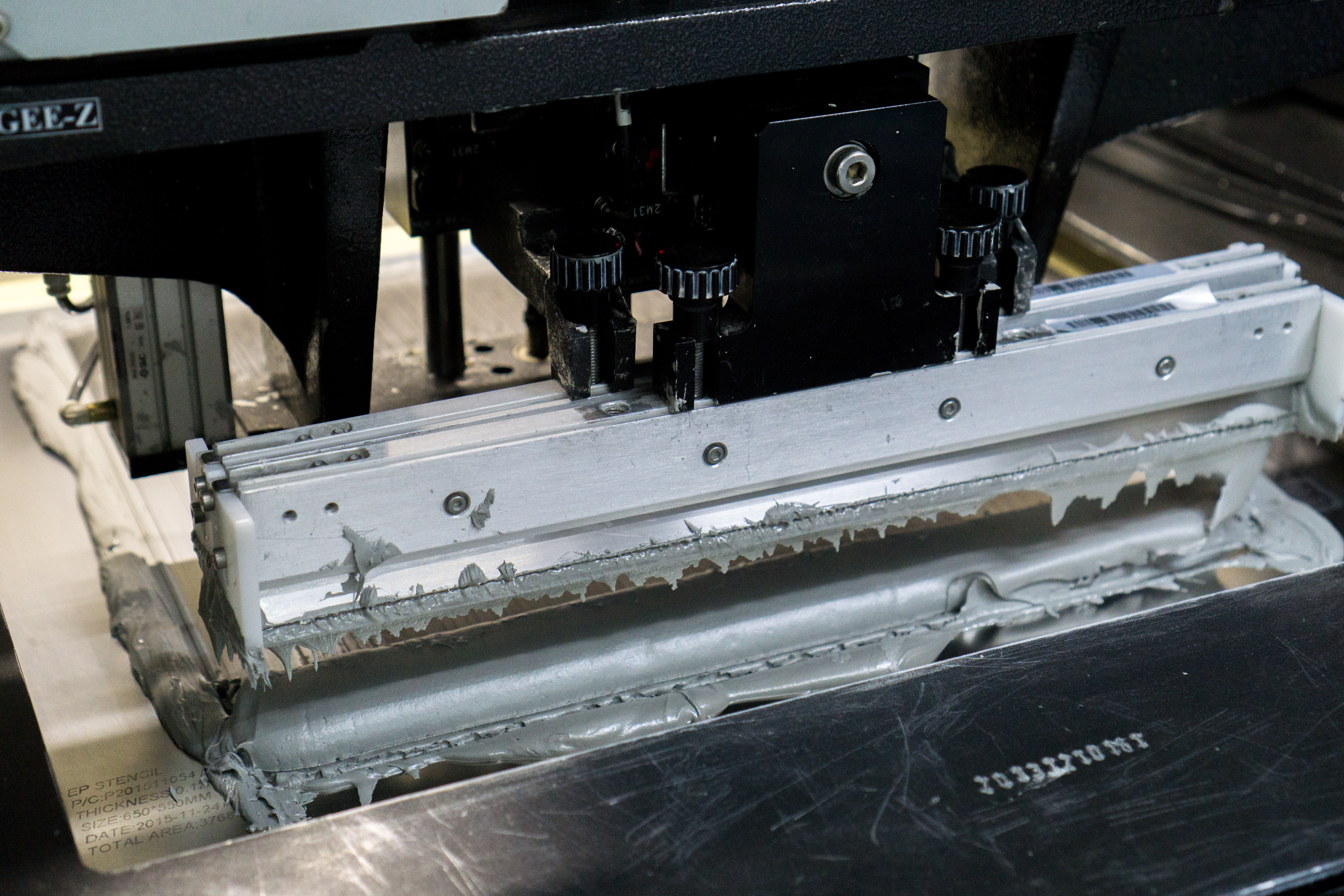

The dual wave soldering machine here will essentially cook the components into place, though that's a simplification of the soldering process. Here's an example video of a wave soldering machine in action.

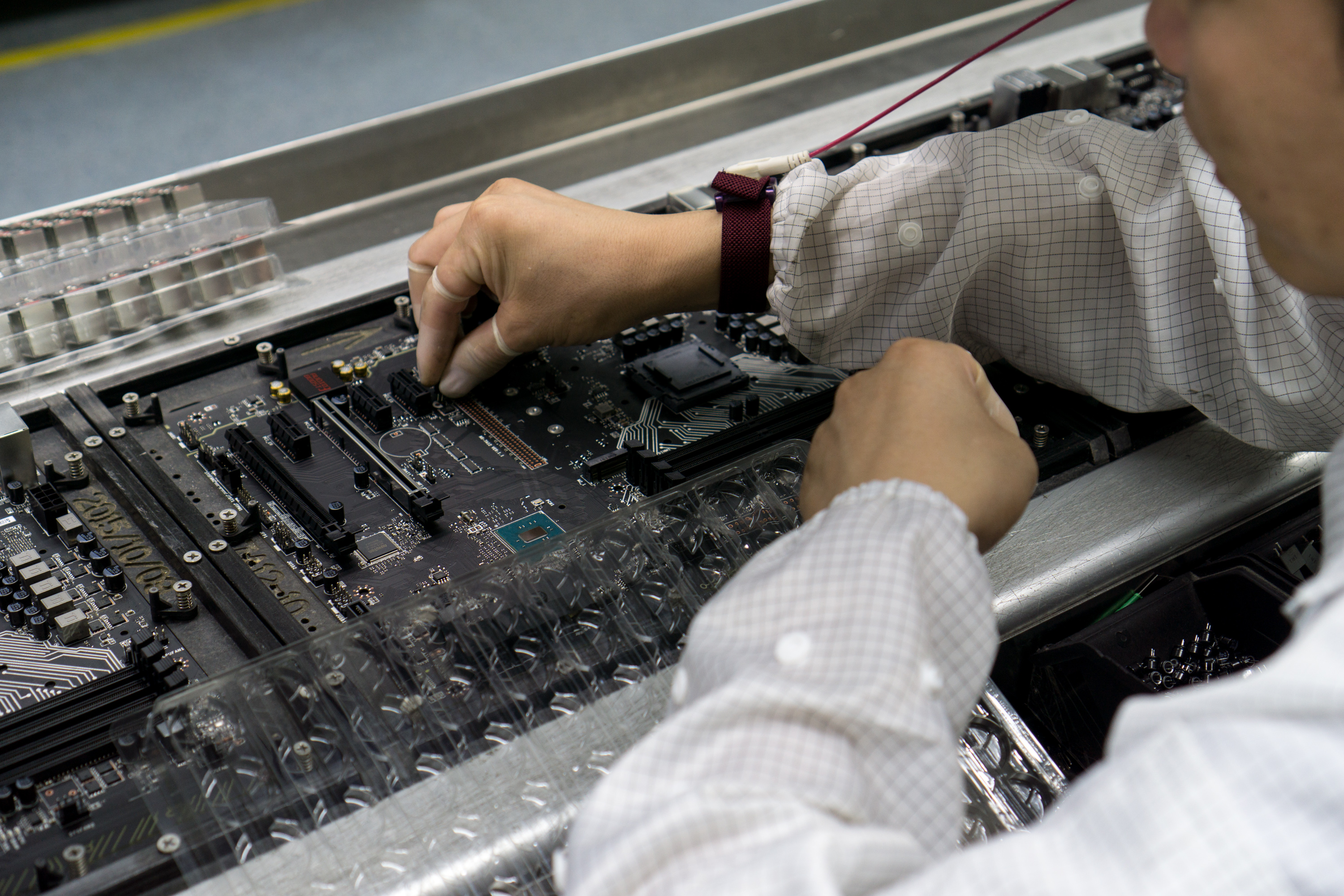

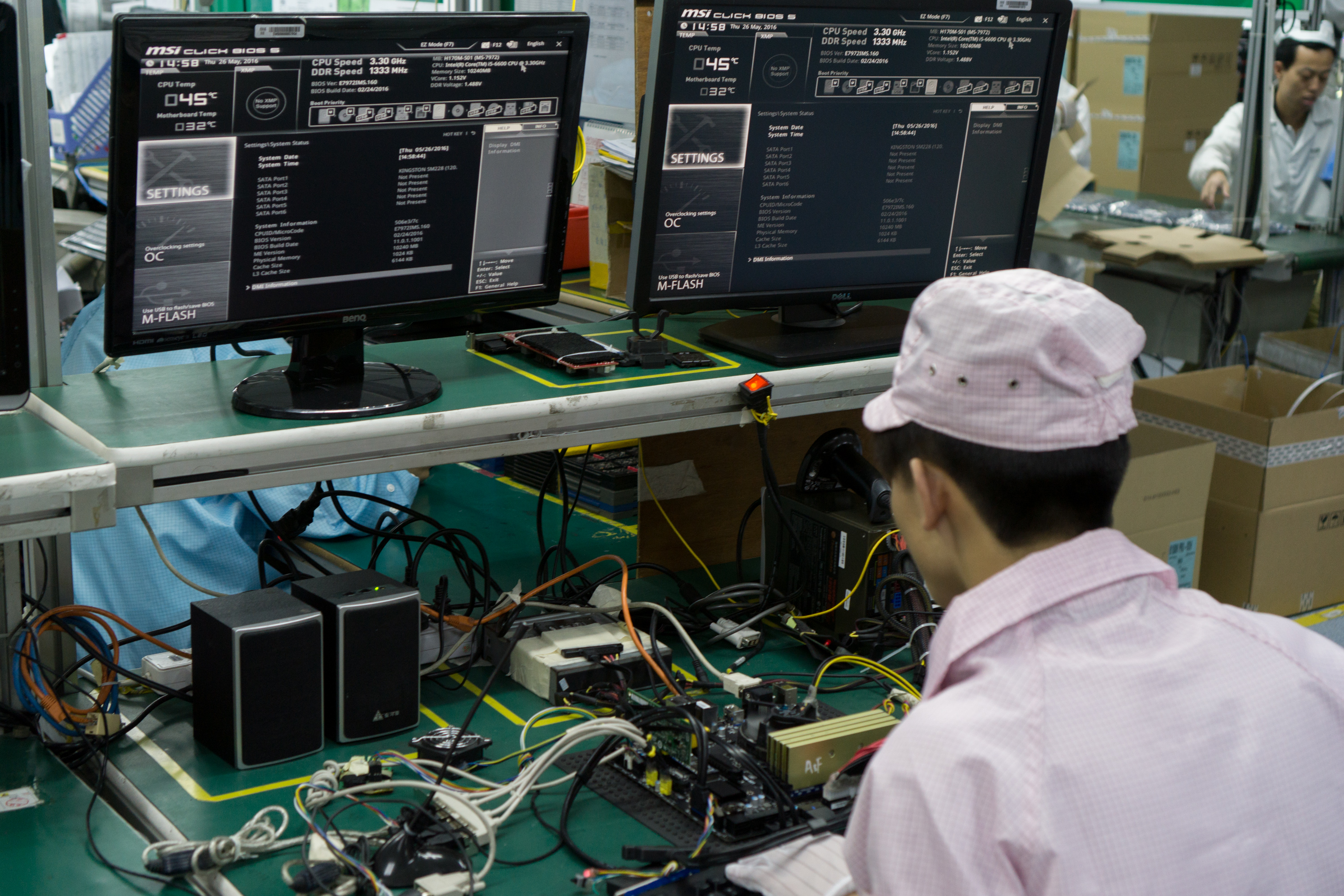

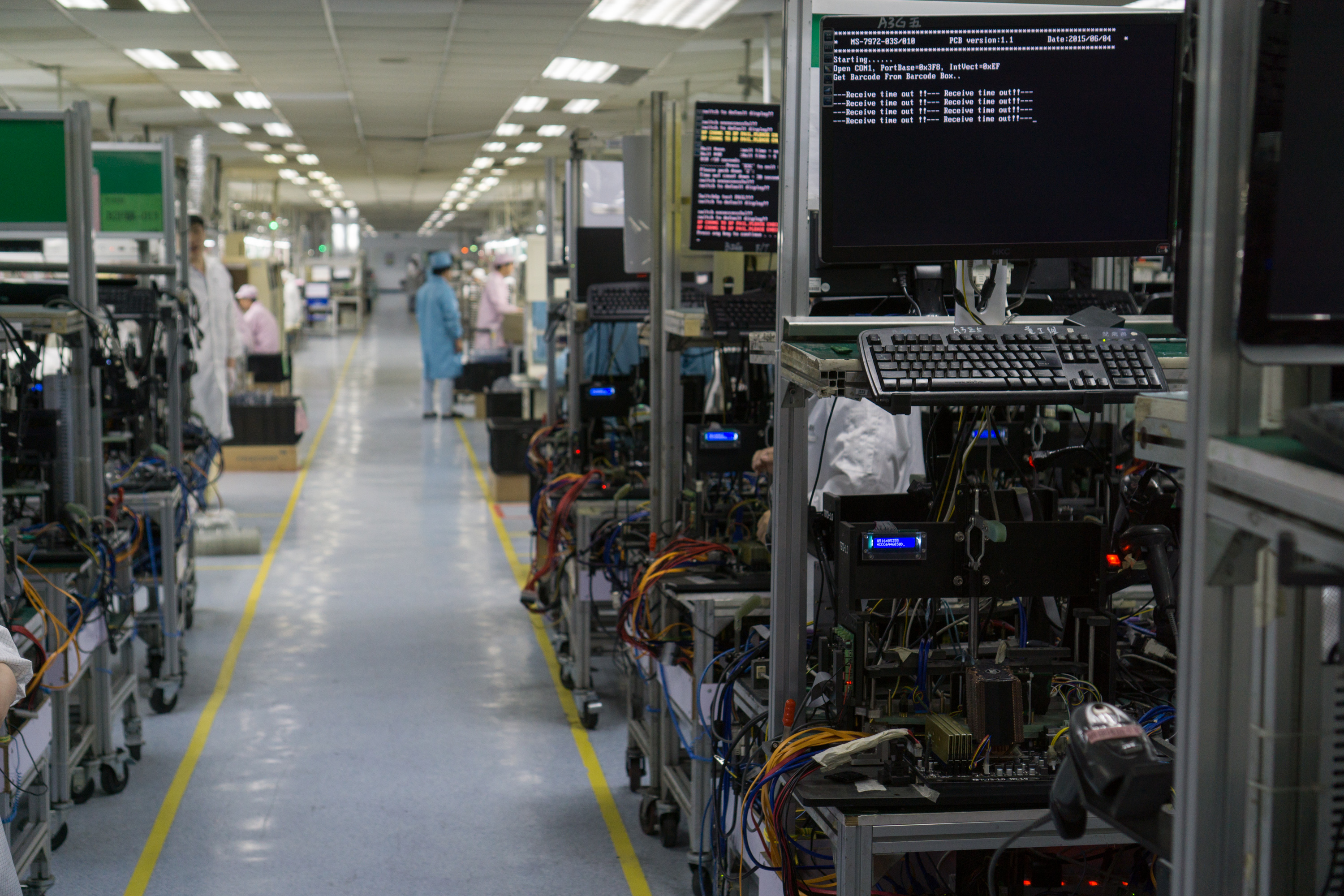

A look at the testing area. After motherboards go through the assembly process, they roll down the line to these stations, where workers plug in components and run diagnostics to ensure there are no issues.

In recent years, MSI has developed some of its own testing tools and procedures to improve its production process. This has helped them test for a wider range of problems and feed the data collected back into R&D, engineering, and operators on the assembly line.

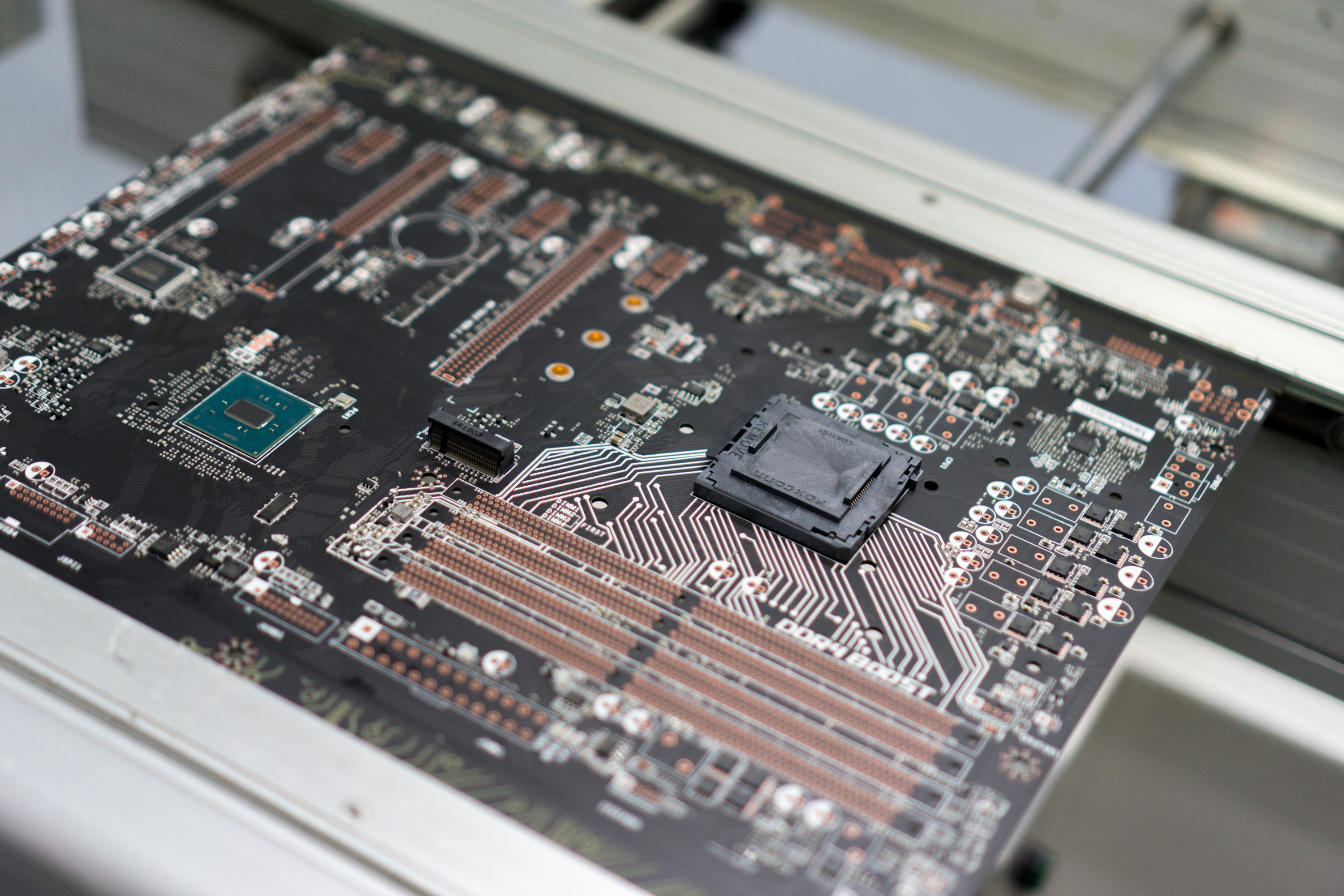

A worker checks the back side of a motherboard to ensure its tracings and components are properly in place before it's packaged up for shipping.

Some inspections are best done by the human eye, but others require machines. MSI's factory director told me that some parts are now so small, humans can't inspect them, so they've designed their own in-house inspection machines. The CPU socket, for example, has more than 2000 tiny pins.

And that's how motherboards are made at MSI. Workers here have ten hour shifts, with two hour production breaks for lunch and dinner. That's a day at MSI's factory, which produces around 60,000 motherboards every single day, and another 30,000 graphics cards.

But wer're not done with our tour yet: in the next 12 slides, hardware EIC Tuan Nguyen takes us through MSI's HQ in Taiwan.

The room above is where many of MSI's products are designed. Concepts, prototypes, and refinements are all sketched out. The product design team goes through many iterations before arriving at a final design. Materials and colors are selected here.

There are large whiteboards all over the room for attaching various inspirational designs and clippings. Everything from car photos, to jewelry, to houses are put on the board. The design team then uses the design collage to create an initial design.

The white board doors slide open to reveal a treasure trove of mockups and prototype designs that didn't make the cut. Unfortunately, we weren't allowed to snap photos of the early prototypes.

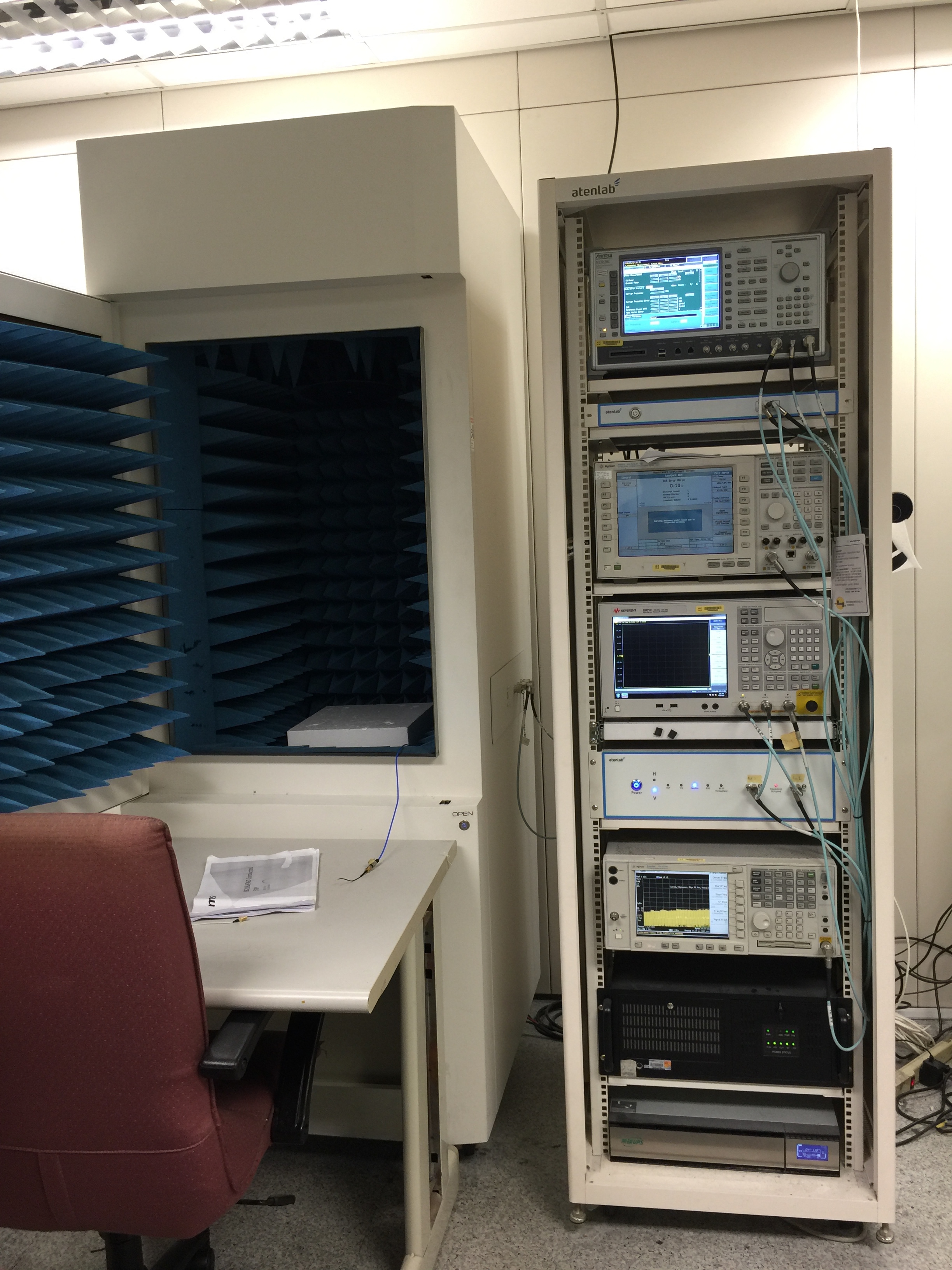

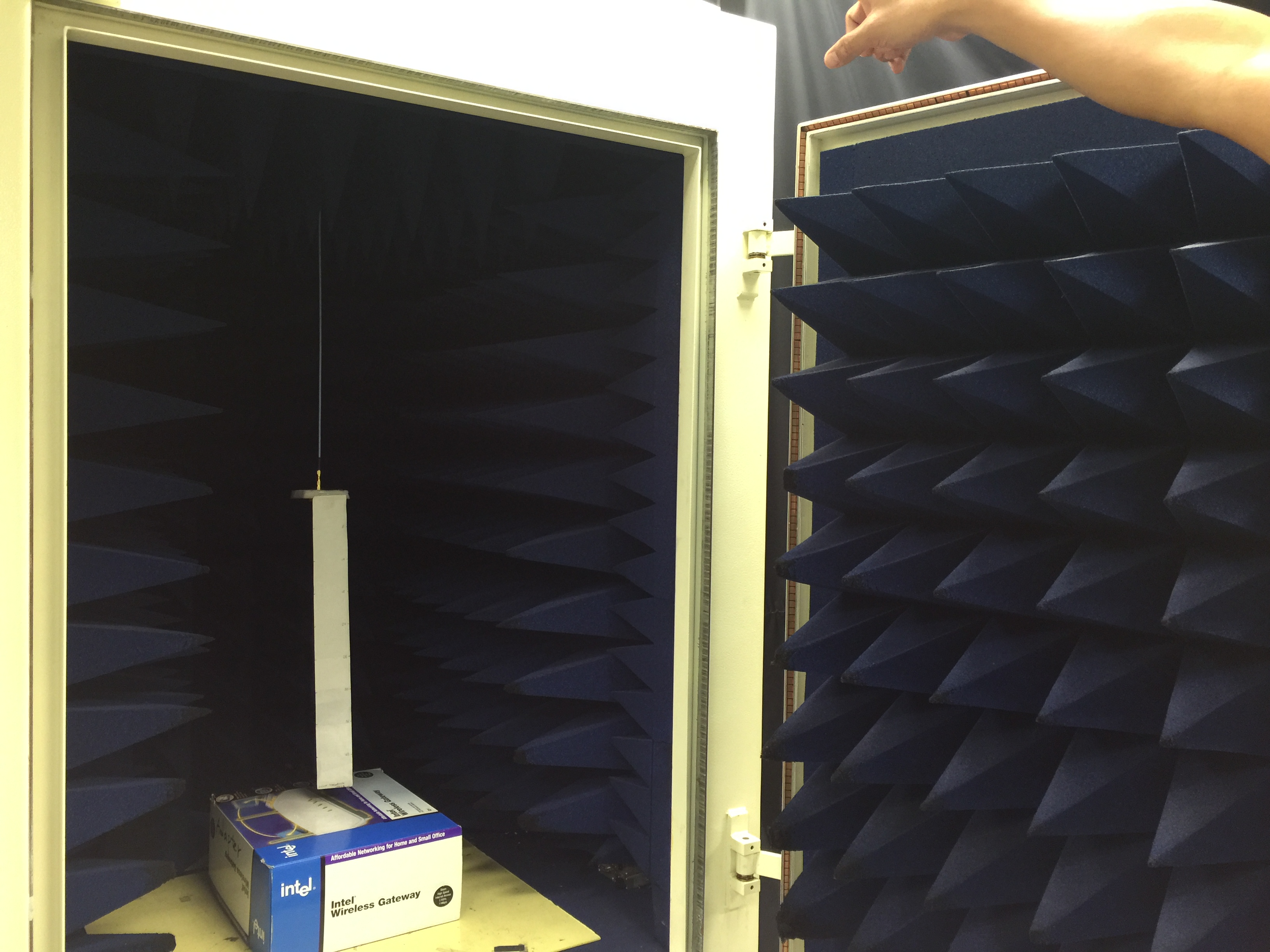

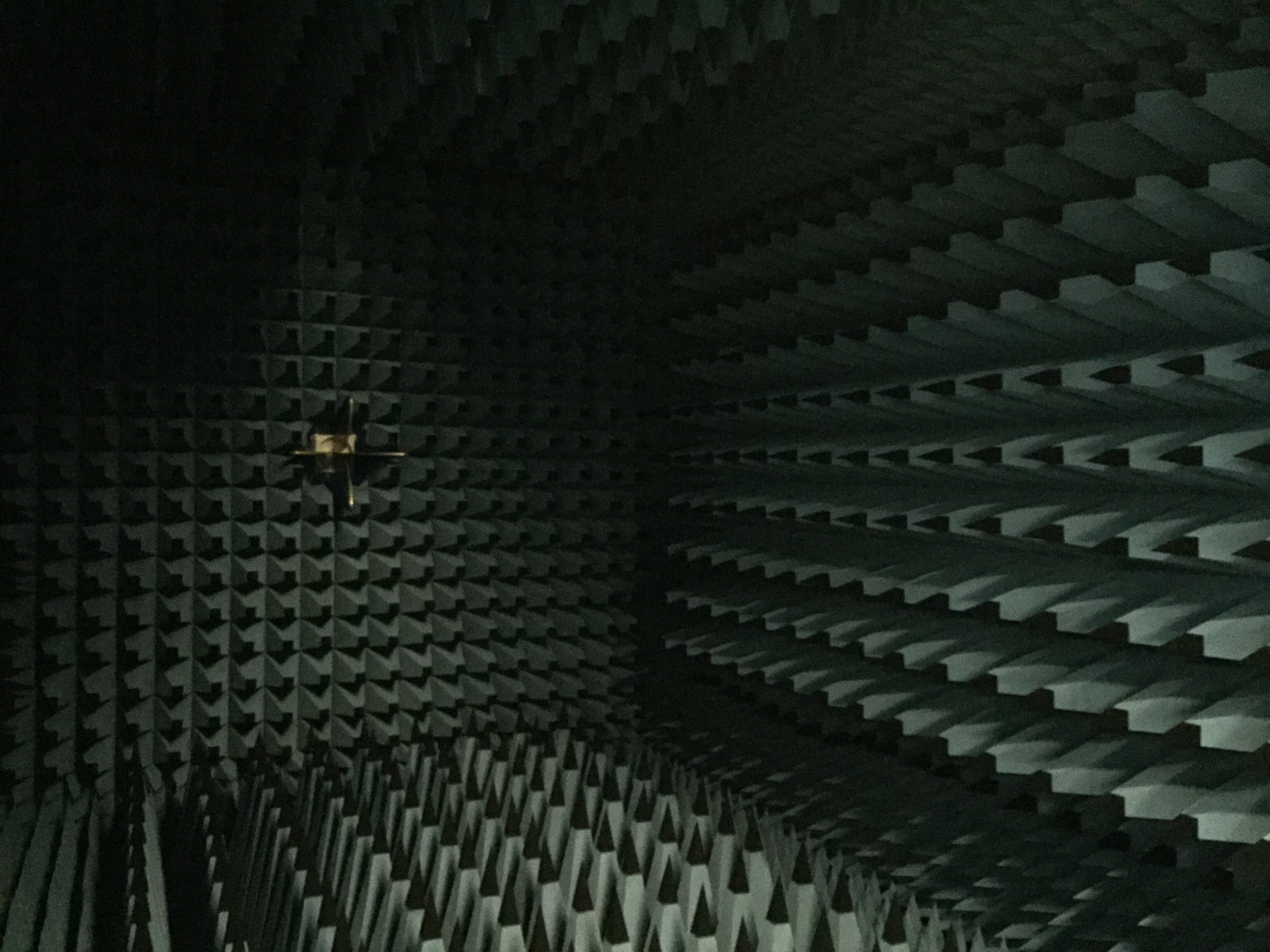

Here's one of MSI's many anechoic chambers. This one in particular plays hosts to testing of wireless devices. The room is completely void of outside radio frequencies. Step into here, and the signal on your mobile phone drops off completely. If you're ever stuck in here, there's no chance of dialing for help.

One of MSI's engineers walk into another anechoic chamber to demonstrate just how large they can be. In fact, as big as the one in the above photo was, there are anechoic chambers around the world that are much larger.

We were told not to touch the special foam sound insulation. Apparently, there's a special coating on them that is a bit hazardous for humans, especially if you forget and eat food with your hands or rub your eyes. We touched them anyway and the blue coating feels like a fine dust.

With the door closed, we couldn't hear anything from the outside. It was complete silence. Staying in the chamber for any amount of time above five minutes started to make us feel uncomfortable. We were told that if you stay in an anechoic chamber for long enough, you actually can hear the blood flowing through your ears, as well as your own heartbeat.

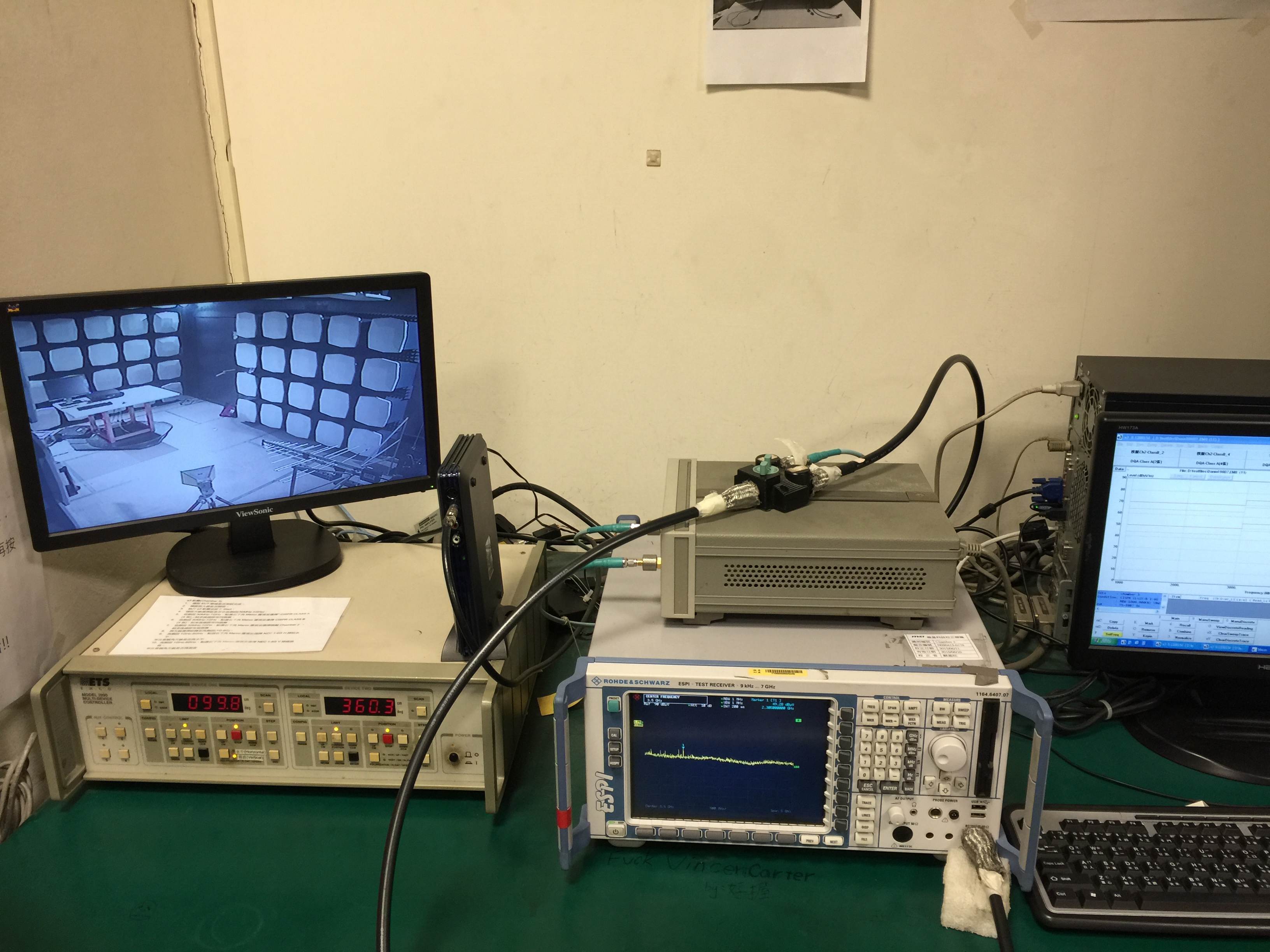

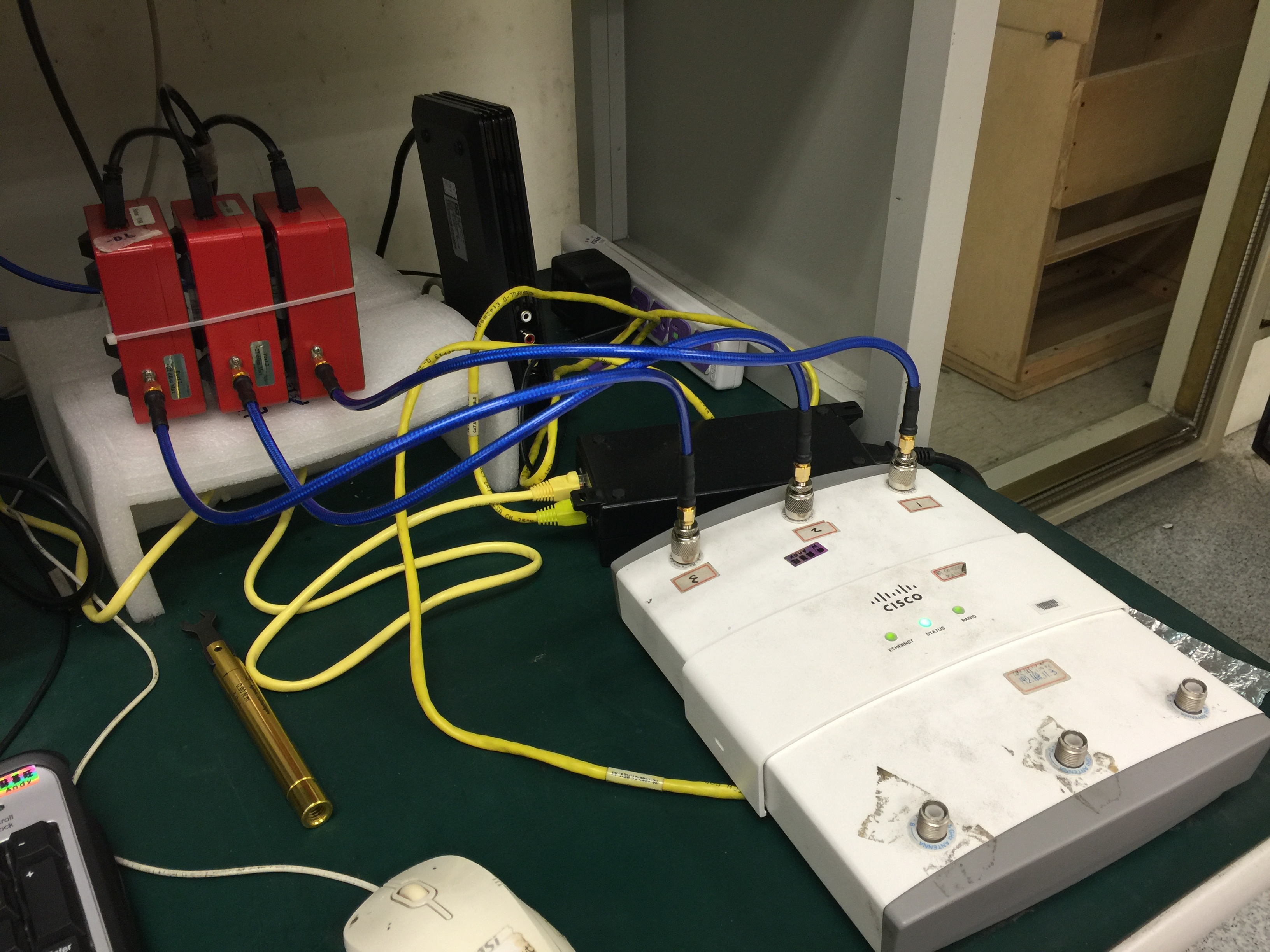

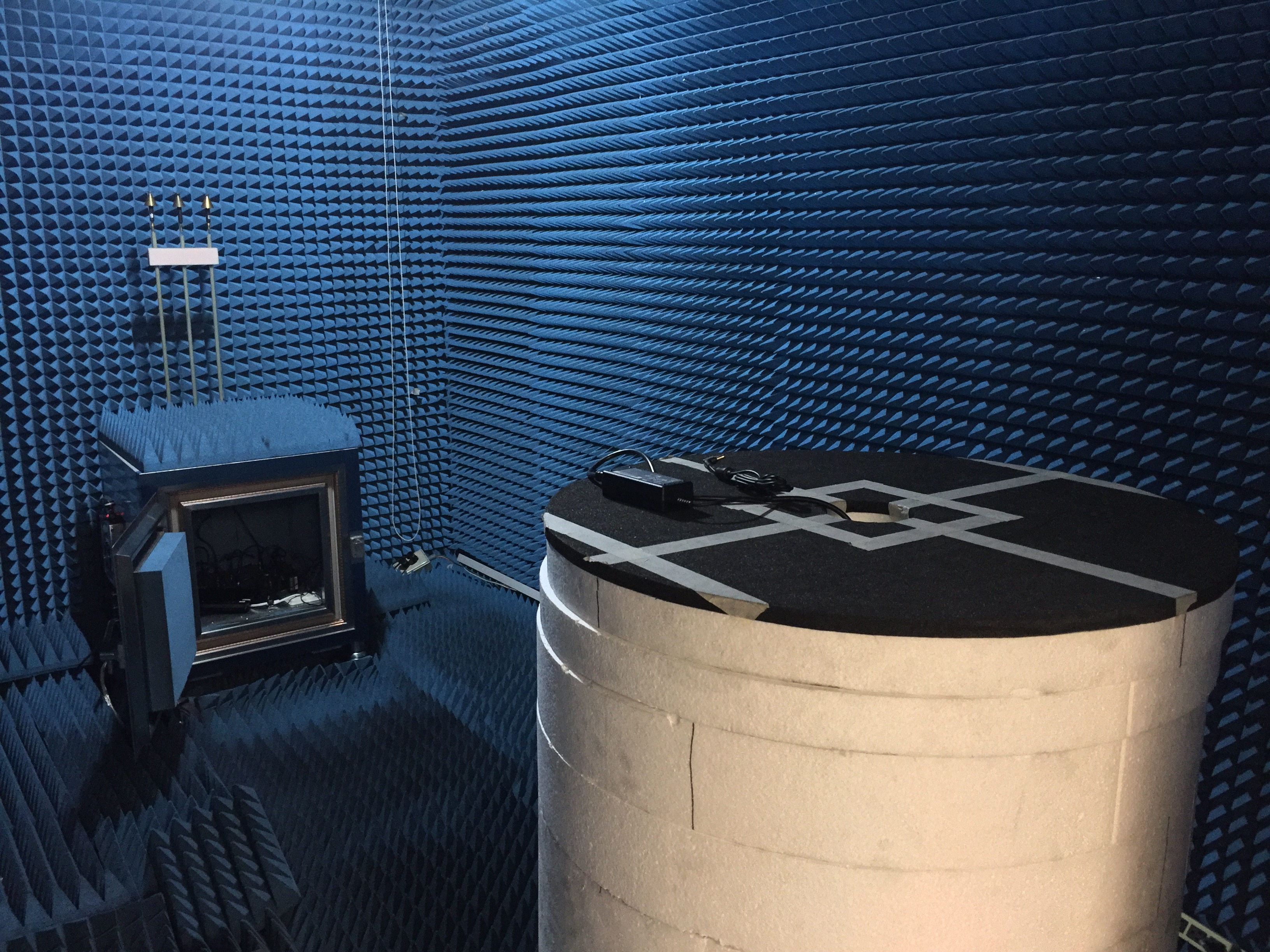

Above is another smaller anechoic chamber used to test Bluetooth- and Wi-Fi-related devices. For example, a router can be placed inside the box at the end, which is sealed from radio interference. The antennas are connected to the box itself, and the box has antennas on the outside. This ensures exact testing of antenna performance.

The pedestal closer to the camera is where receiving devices are placed.

Wes has been covering games and hardware for more than 10 years, first at tech sites like The Wirecutter and Tested before joining the PC Gamer team in 2014. Wes plays a little bit of everything, but he'll always jump at the chance to cover emulation and Japanese games.

When he's not obsessively optimizing and re-optimizing a tangle of conveyor belts in Satisfactory (it's really becoming a problem), he's probably playing a 20-year-old Final Fantasy or some opaque ASCII roguelike. With a focus on writing and editing features, he seeks out personal stories and in-depth histories from the corners of PC gaming and its niche communities. 50% pizza by volume (deep dish, to be specific).

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Every Friday

GamesRadar+

Your weekly update on everything you could ever want to know about the games you already love, games we know you're going to love in the near future, and tales from the communities that surround them.

Every Thursday

GTA 6 O'clock

Our special GTA 6 newsletter, with breaking news, insider info, and rumor analysis from the award-winning GTA 6 O'clock experts.

Every Friday

Knowledge

From the creators of Edge: A weekly videogame industry newsletter with analysis from expert writers, guidance from professionals, and insight into what's on the horizon.

Every Thursday

The Setup

Hardware nerds unite, sign up to our free tech newsletter for a weekly digest of the hottest new tech, the latest gadgets on the test bench, and much more.

Every Wednesday

Switch 2 Spotlight

Sign up to our new Switch 2 newsletter, where we bring you the latest talking points on Nintendo's new console each week, bring you up to date on the news, and recommend what games to play.

Every Saturday

The Watchlist

Subscribe for a weekly digest of the movie and TV news that matters, direct to your inbox. From first-look trailers, interviews, reviews and explainers, we've got you covered.

Once a month

SFX

Get sneak previews, exclusive competitions and details of special events each month!