So, it's the mirrors. Freakishly accurate-to-an-atom-width mirrors are one big reason your modern GPU is so damned expensive

That and the lasers firing at tiny flying droplets of tin...

Profiteering, the AI boom, latterly the looming threat of tariffs—there are a lot of reasons why computer chips have become so expensive. But you probably wouldn't have guessed another major reason is mirrors. More specifically, the insanely perfect mirrors inside the latest EUV lithography machines used to manufacture the most advanced chips.

That's according to YouTube channel Asianometry, which has done a deep dive into the incredible engineering of the mirrors used in advanced chip manufacturing. The latest machines from ASML, as used by TSMC for its most advanced N4 and N3 chip production processes and Intel for its Intel 7 and 4 nodes, rely on extreme ultra-violet light 13.5 nm in wavelength.

Controlling and focusing that light on the silicon wafers—which, in the very simplest terms, is how you etch a computer chip from a wafer—is a very difficult process. To cut a long story short, these machines use a series of mirrors to do that. The catch is the focus and reflection control needs to be accurate to within 260 picometers or 0.26 nanometers, slightly smaller than the 275 picometers of a water molecule.

That's accurate to 260 picometers for the entire system of multiple mirrors, which is 10 mirrors and up to 12 reflections depending on configuration. Anyway, when you do the sums, you end up with a required surface accuracy for each individual mirror of, at worst, 53 picometers. And that, according to Asianometry, is about the same as the atomic radius of the smallest atom, hydrogen.

So, how is this incredible accuracy achieved? First, a substrate is formed and polished to the desired geometry using traditional optical techniques but without the full accuracy and consistency required. Then a process known as ion beam figuring is used to essentially flatten surface imperfections at an atom level by firing high energy particles at the substrate.

After that, layers of molybdenum and silicon just a few nanometers thick are deposited on the surface using a process known as magnetron sputtering. That involves firing ions at blocks of molybdenum or silicon, which in turn then eject atoms which can be made to settle on the substrate.

Around 50 alternating layers of molybdenum and silicon are needed to achieve the multi-layer constructive interference reflection characteristics required for EUV light. If you're keeping up so far, props, this stuff is fiendishly complicated. And that, of course, means it's mind-bogglingly expensive.

The biggest gaming news, reviews and hardware deals

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

Of course, this series of incredibly accurate mirrors is but one part of an EUV lithography machine. Another mind-bending feature is the generation of the EUV light in the first place. Roughly speaking, that involves firing droplets of molten tin, each of which is then struck by a laser pulse, once to flatten the droplet, a second time to vapourise it, at which point is emits the desired 13.5 nm wavelength of EUV light.

The whole thing is completely bananas, frankly, which is why an ASML EUV machine costs hundreds of millions of dollars and the factories or fabs that house them cost billions of dollars.

Oh, and the chips that go into our gaming machines are getting more and more expensive. TSMC makes all of Nvidia and AMD's current GPUs, the RTX 50-series and RX 9000-series respectively, and uses ASML's incredibly expensive EUV machines with their unbelievably accurate mirrors to produce those GPUs. And so now you have just a slightly better understanding why graphics cards are so expensive these days. Those mirrors aren't the only reason, but they do make a significant contribution.

Best CPU for gaming: Top chips from Intel and AMD.

Best gaming motherboard: The right boards.

Best graphics card: Your perfect pixel-pusher awaits.

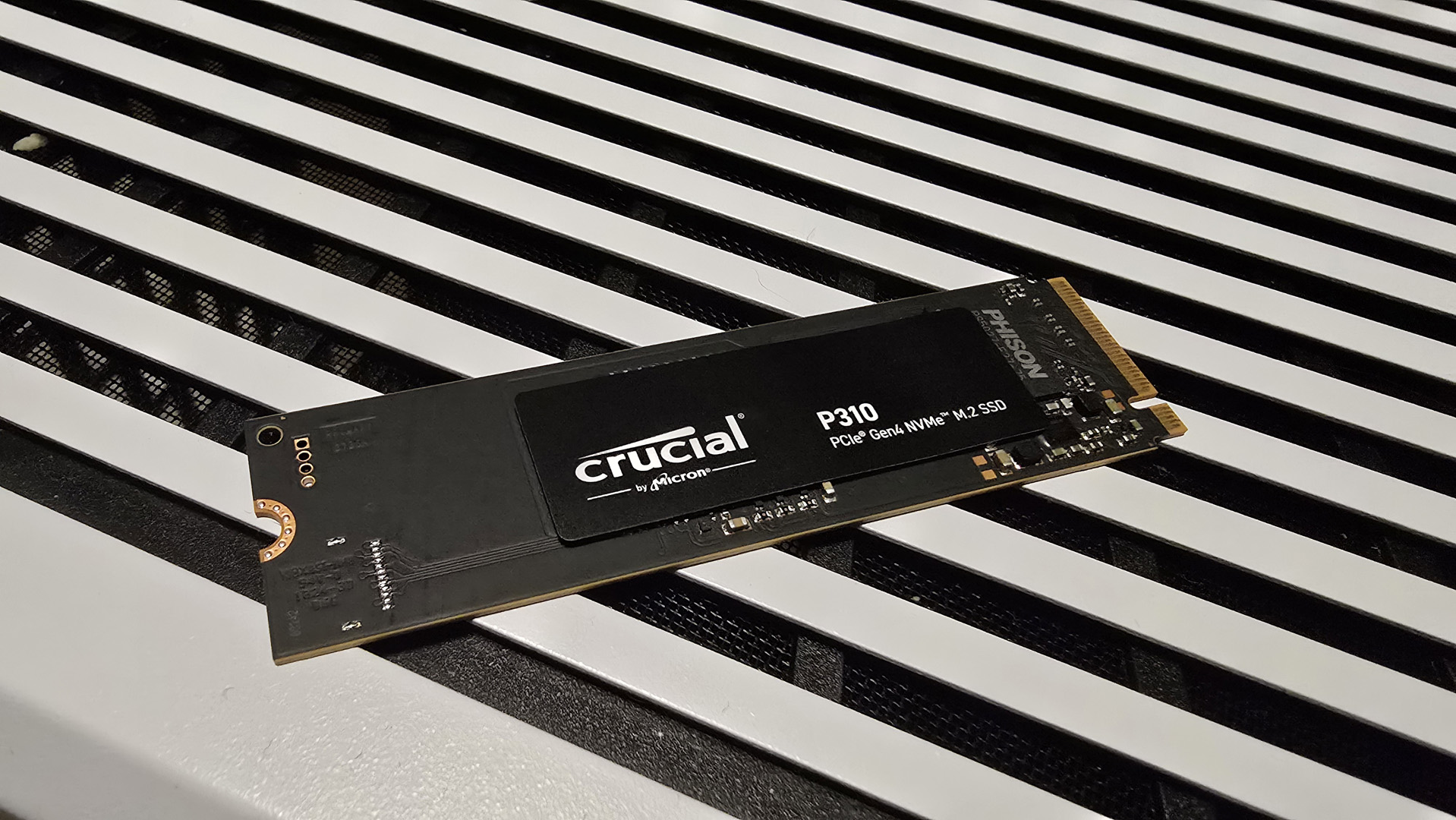

Best SSD for gaming: Get into the game first.

Jeremy has been writing about technology and PCs since the 90nm Netburst era (Google it!) and enjoys nothing more than a serious dissertation on the finer points of monitor input lag and overshoot followed by a forensic examination of advanced lithography. Or maybe he just likes machines that go “ping!” He also has a thing for tennis and cars.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.